Linco

LEAN

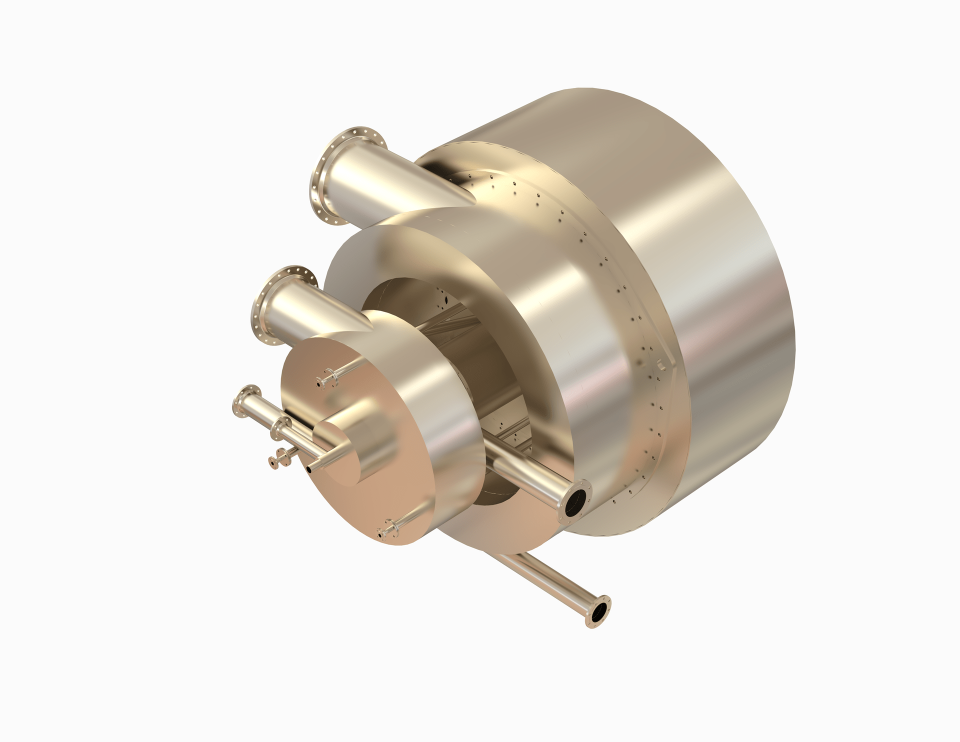

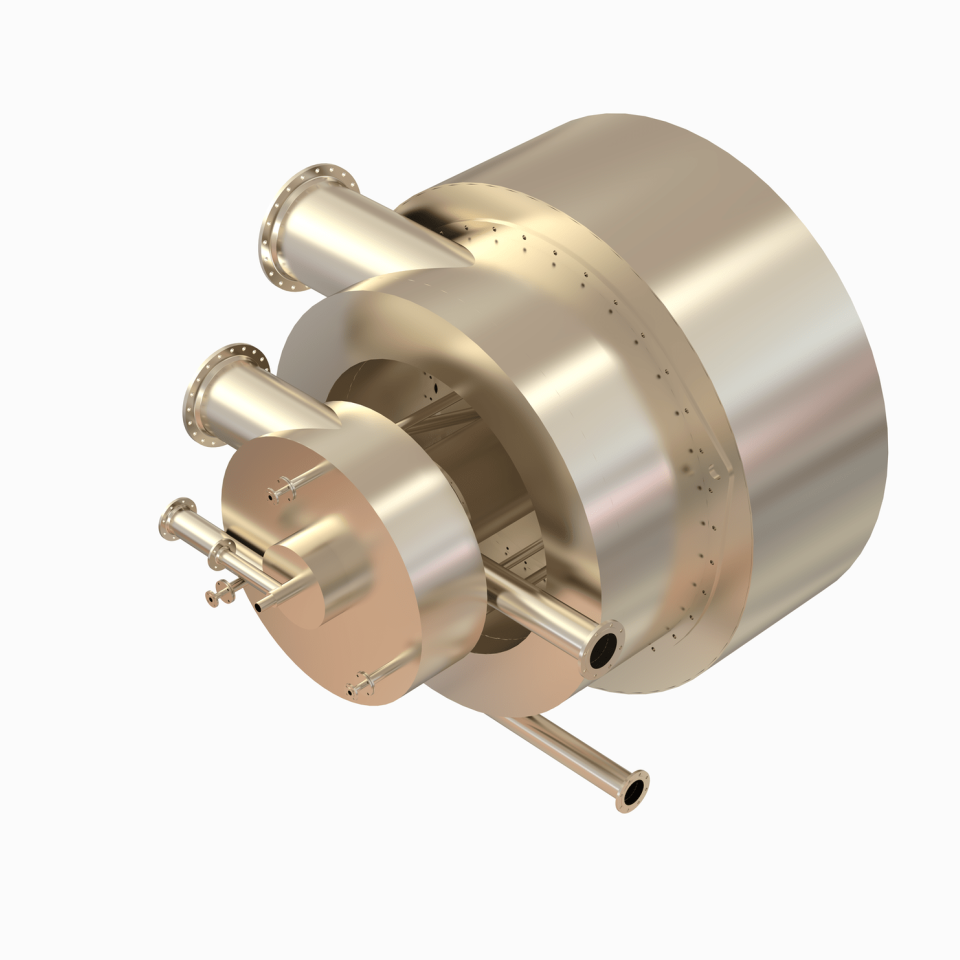

BURNER OPERATING WITH VERY LOW CALORIFIC FUEL

Main charecteristics :

- Firing with high stability without rich fuel support

- designed for maximum thermal efficiency

- Range : 1 – 60 MW

- Performant and operational flexibility

- Significant cost saver

LOW LHV Fuels : blast furnace gas, coke oven gas, pyrolyse gas, process gas, ...

State-of-the-Art !

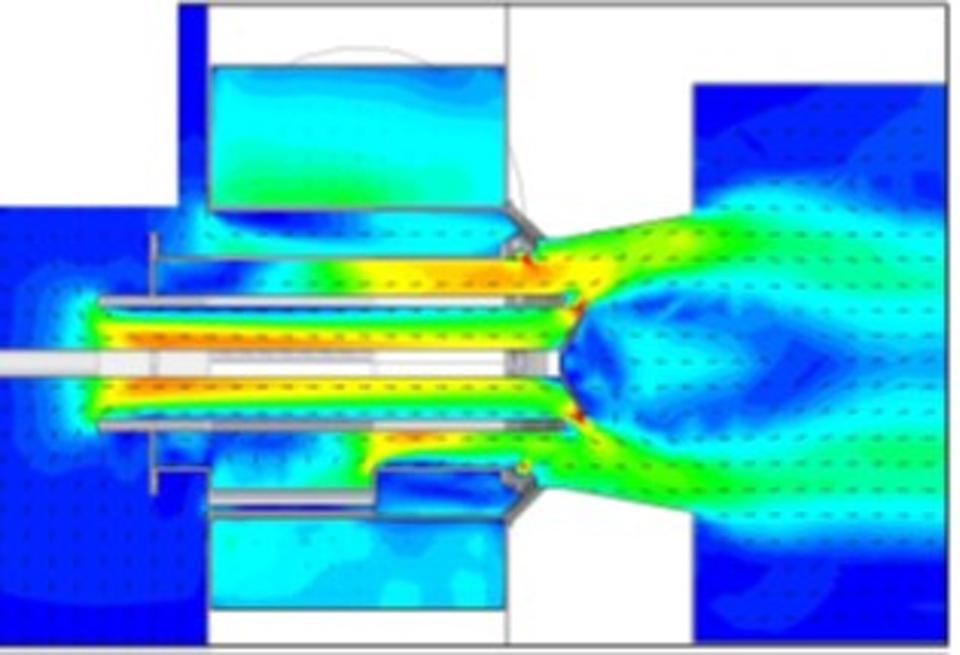

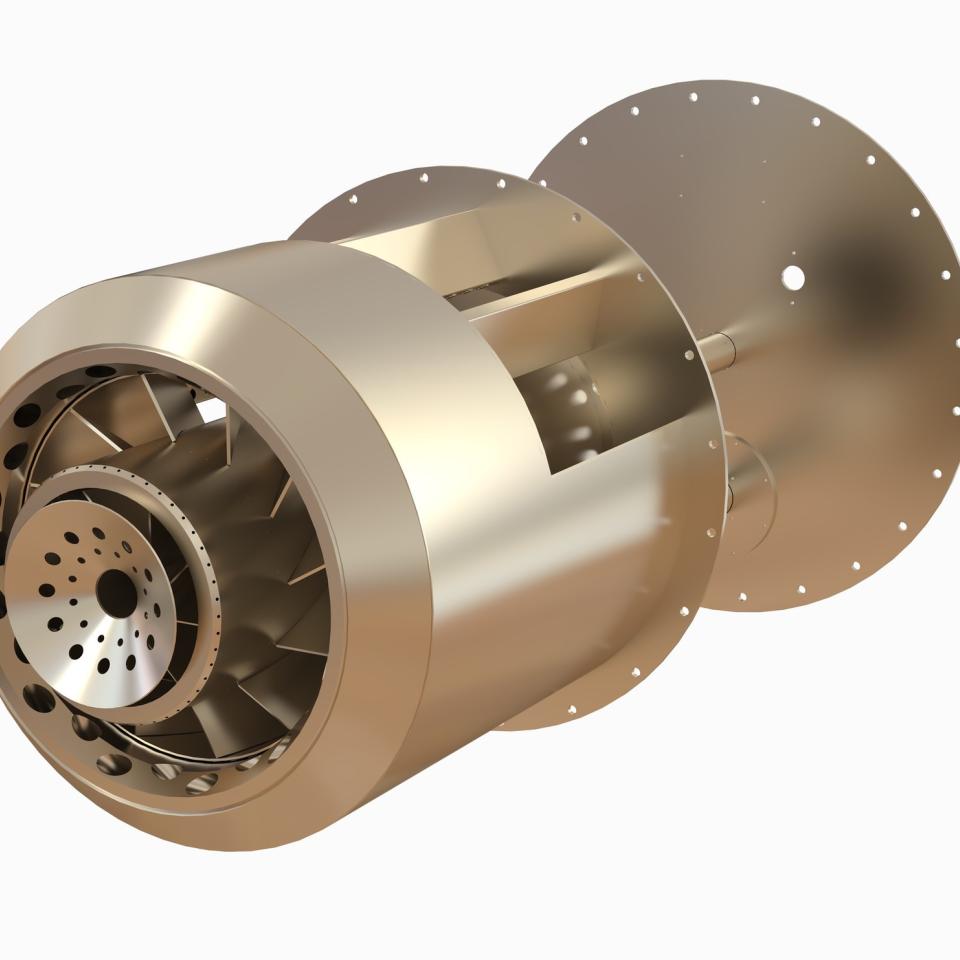

Burners using lean gas or residual gas generally comprise a number of coaxial ducts or pipes arranged to supply a ring or rings of fuels centred on the axis of the burner and feeding liquids to the burner nose. These fuels are generally distributed in or around the circumference of a combustion air stream. The purpose of these elements is to achieve a sufficient fuel-air mixture to achieve localised and stabilised combustion at the burner nose.

Applications :

- Steel work plants, or power station burning process gas from steel industry

- Hot or cold furnaces, boilers, combustion chambers, waste gas incinerators