Nox

Limiting

We have the expertise to design and install SNCR-deNOx (Selective Non Catalytic Reduction) injection systems for your new or existing combustion process and combine this with state-of-the-art post-combustion emission control.

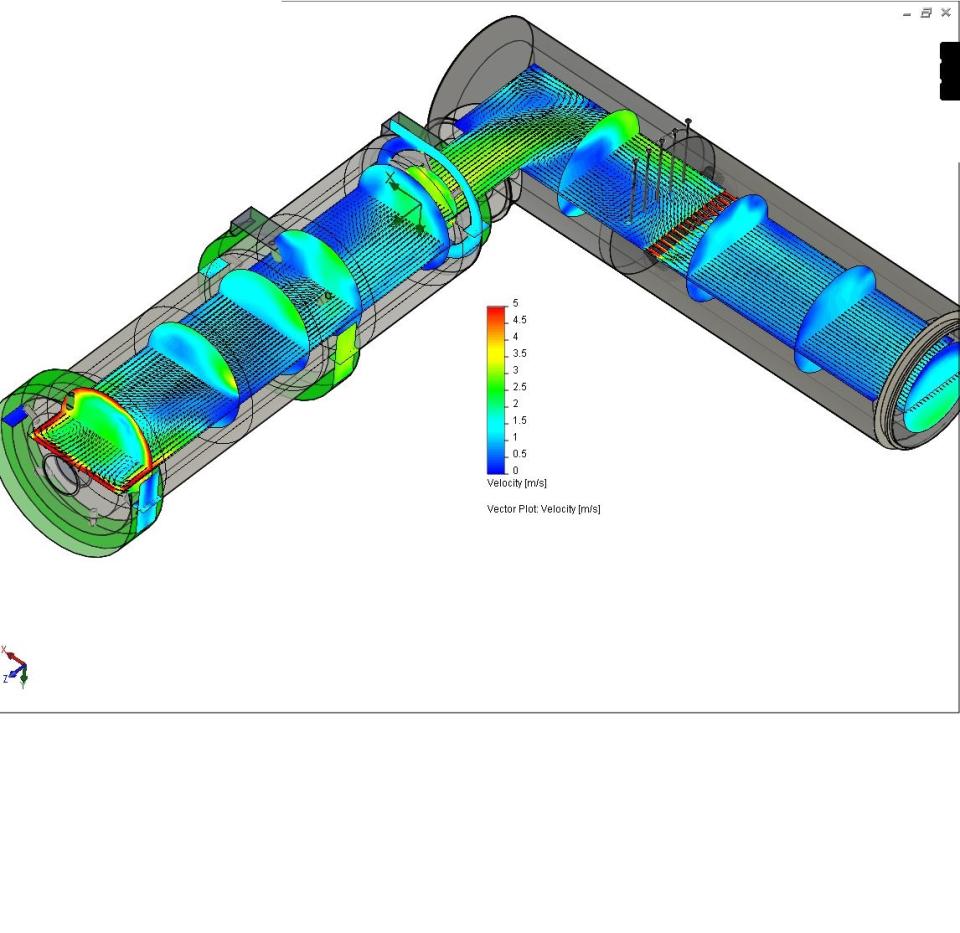

Proper flow and temperature distribution can be modelled by our L-Inc® in-house specialist in Computational Fluid Dynamics (CFD). Our flue gas/reagent (ammonia/urea) mixing skills ensure that our SCR systems minimize ammonia slip and maximize NOx control.

Our systems can also be integrated in SCR-Catalyst system.

For the atomisation of liquid urea/ammonia solutions we have complete systems with a capacity of 1 - 80 l/h.

- For small quantities of 0 - 10 l/h a Microskid is well suited.

- For larger quantities of 0 - 30 l/h and 0 - 80 l/h, we offer our skid-mounted systems with 1 or 2 pumps.

Each system is equipped with its own PLC control that regulates the dosage of urea/ammonia solution on the basis of the NOx measuring signal provided by the customer.

In need of more emission control ?

to provide our customers an integrated approach for design of emission control units, L-Inc® network and cooperation with specialist in this field are at our customers disposal.

- emission monitoring & control tools

- high temperature filtration

- scrubbers

- cyclones & multicyclones

- Bag house filter