Thermal Oxidizer

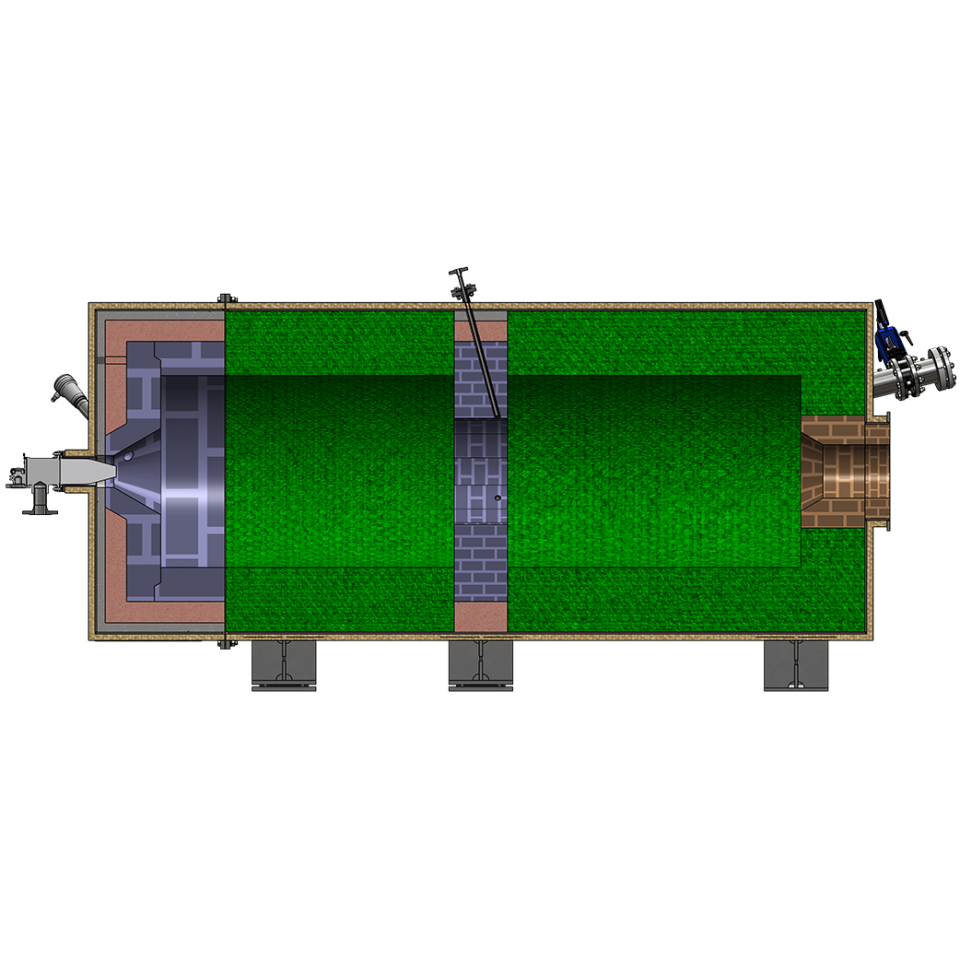

Our piece-of-ART for liquids & waste gases thermal oxidizers effectively destroy 99.9% of the air toxins, odours and volatile organic compound (VOC) and hazardous air pollutant (HAP) emissions that are discharged in industrial process exhausts.

L-Inc® thermal oxidizers manage a variety of process parameters, such as variable analysis waste flow rates, calorific values, temperature and oxygen content.

USP’s :

- Skid mounted reduces installation time and costs

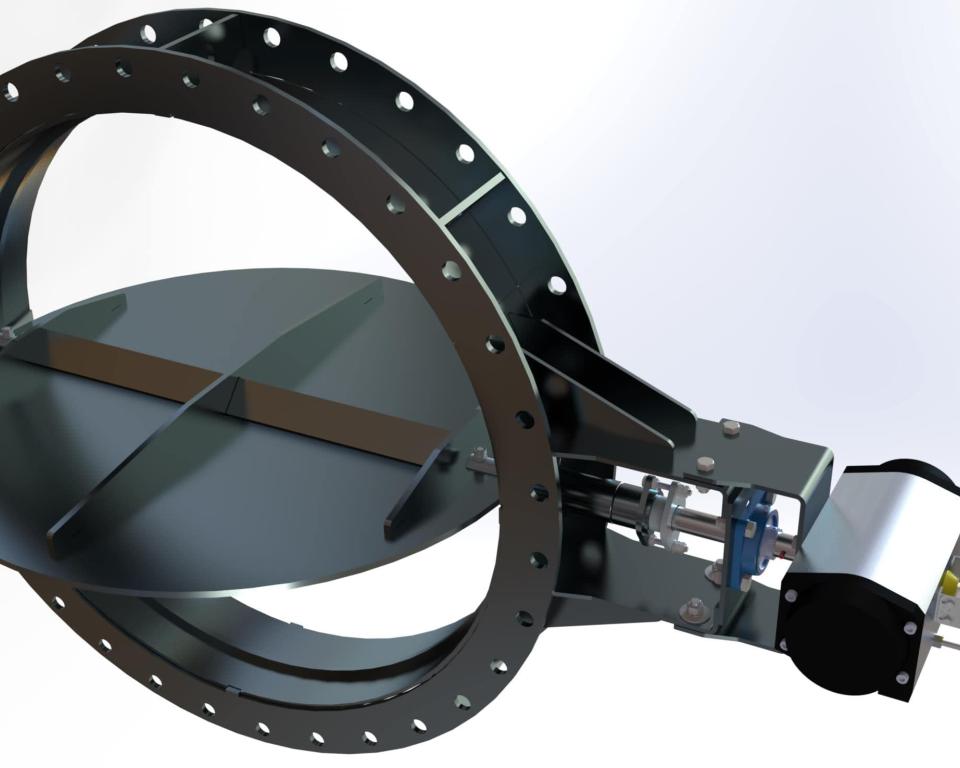

- Horizontal-or vertical design independent waste process streams can be injected separate-or simultaneously.

- Reduced Nitrogen Oxide (NOx) and Carbon Monoxide (CO) Output

- High performance refractory lining and a minimum residence time to ensure the elimination of harmful components

Typical Applications :

- spent solvent streams halogenated waste streams

- Sulfur plant tail gas streams

- Waste containing salts

- Acrylonitrile process wastes

Ideal solution in mixing operations, tank vents & loading stations with variable process flow rates and vapor concentrations.

Effective VOC management can be achieved using efficient pollution control equipment.