Linco

Max

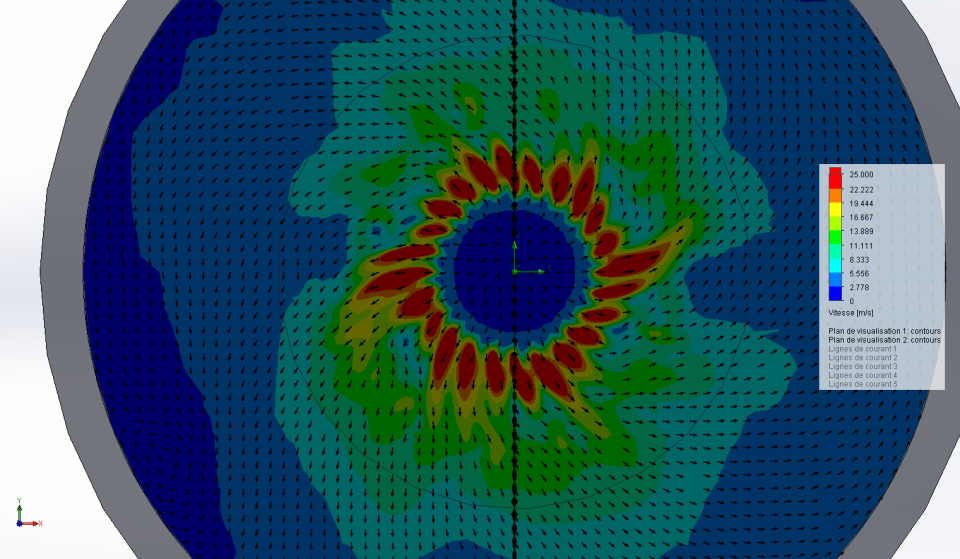

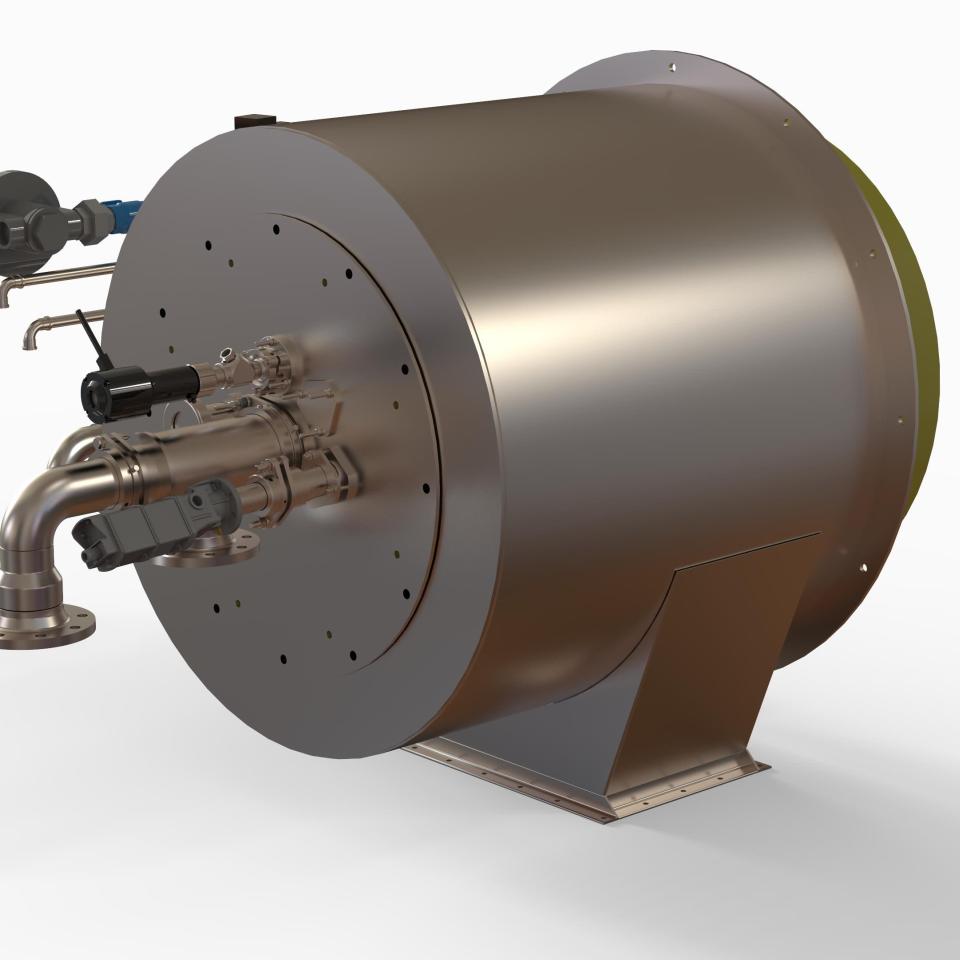

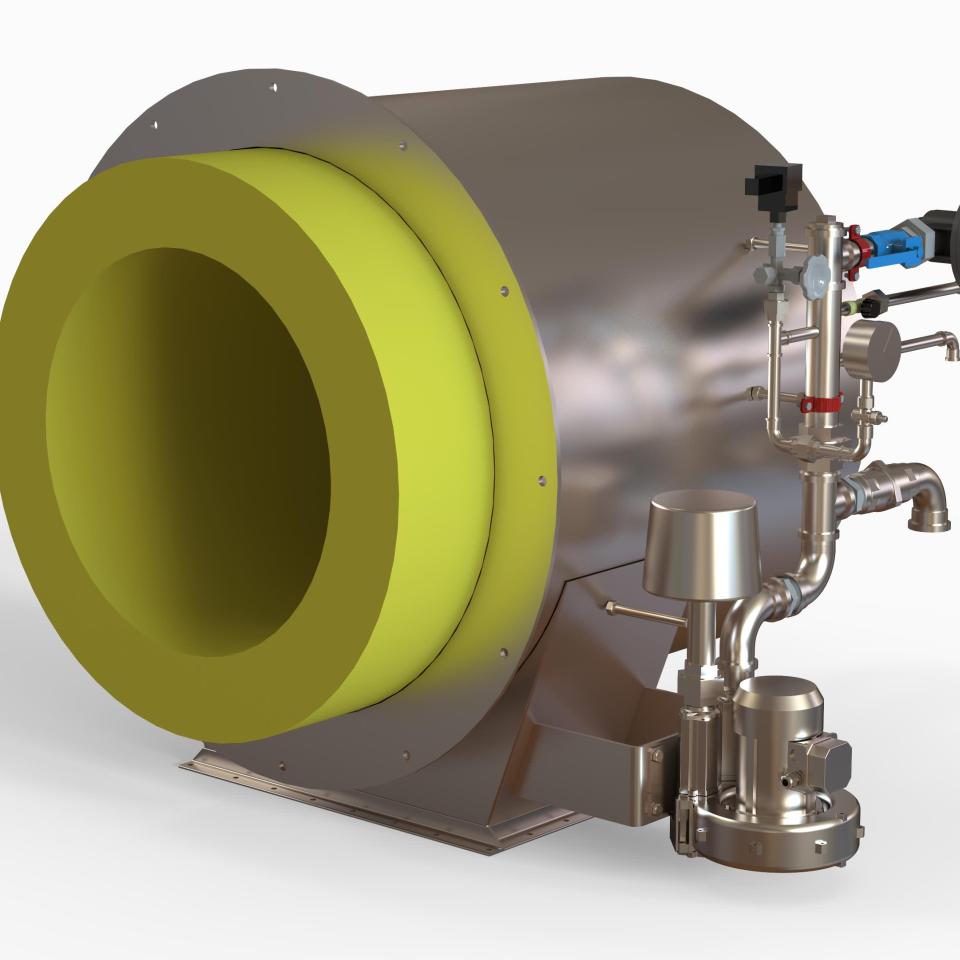

L-incoMaX® means tailor made burner solutions in a standard range of 1-60 MW. This means they are designed to our customer’s specific requirements. Top performance in quality, reliability and very low flue gas values (for example: LOW-NOx)

Tailored to your fuel :

- Natural gas, diesel, HFO, biogas, H2, O2

- Spent acids, acids and leaching

- Coke gases, lean gases, synthesis gases, H2S gases, tail gases

- Sulphur, and nitrogen-based waste, liquid waste

- Waste water, solvents, chlorinated, brominated and halogenated gases and (slurry) liquids

Features:

- Various burner materials (carbon-and stainless steel, alloy, ...

- High temperature and high pressure versions

- Different nozzle systems for the best possible atomisation quality

- Optional burner system equipment